After completing her PhD at IRB on the development of anode materials for lithium-ion batteries, Dr Raić furthered her expertise at the Chemical Institute in Ljubljana, in the Laboratory for Advanced Battery Systems. Her experience spans national and international projects, funded by Croatian and European bodies and carried out alongside renowned researchers and research centres. All this has built a solid foundation for her current work: developing batteries that are more efficient, longer-lasting and sustainable.

A Battery That Can Withstand the Arctic and the Sahara?

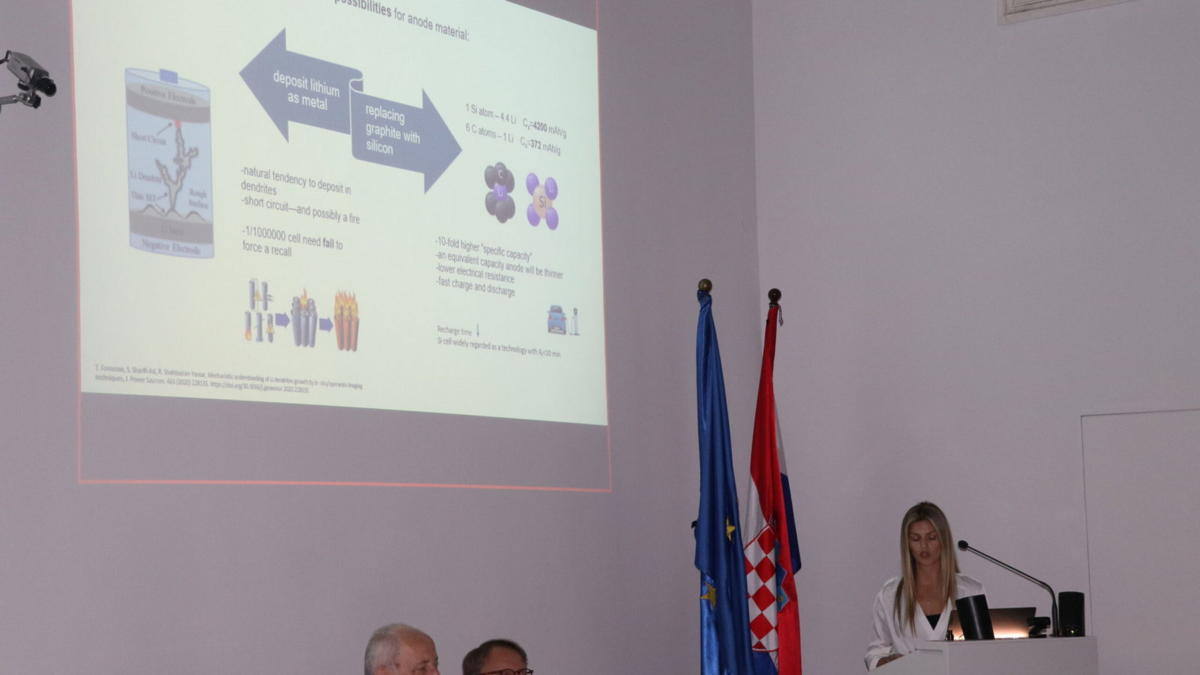

“I’ve always been drawn to the idea of using my knowledge to create solutions that have a tangible impact on everyday life,” says Matea. And this isn’t mere rhetoric. Her scientific portfolio is firmly rooted in applicability, from researching silicon nanostructures for lithium-ion batteries to developing new electrolytes for aluminium and magnesium systems.

As part of the LionBat project, the team has set an even more ambitious goal: the holy grail of lithium-ion technology. The primary aim of LionBat is to increase the energy density of existing lithium-ion batteries. The project focuses on developing cells that meet the targets set by the European Commission: storing over 400 Wh/kg, enduring more than 3 000 charge-discharge cycles, and operating reliably in extreme conditions – from icy −40 °C to scorching 80 °C.

Moreover, the scientists are pioneering new methods to apply the active materials – the components that actually store energy – more uniformly onto the metal substrates that form the electrodes.

Why does this matter? Because a more even structure means a more stable battery and a longer service life. In other words, the laboratory isn’t just creating a new battery but optimising a technology that could become pivotal in the transition to a greener, more sustainable future.

Industry Collaboration: From Lab to Market

The LionBat project is no solitary scientific endeavour but a tripartite alliance of academia and industry. The Ruđer Bošković Institute, the Faculty of Chemical Engineering and Technology, and the company Sunceco have joined forces to transform laboratory findings into concrete technological solutions. While collaborations between academia and the private sector in Croatia often remain declarative, this one appears to be the exception. “This synergy with industry not only gives the project strong potential to produce tangible outcomes, but also a sense of responsibility. Our solutions must be not only innovative, but feasible,” stresses Dr Raić.

Working with Sunceco allows for testing and validating results in real production environments, with the goal of achieving a Technology Readiness Level of 4, where scientific prototypes are converted into technologies ready for industrial development.

Inside the Battery: What Really Happens?

Dr Raić doesn’t stop at the battery’s external performance; her scientific curiosity delves into the complex processes occurring within during charge and discharge. This is where operando techniques come in – methods that allow real-time observation of changes inside the materials while the battery is operating.

“Looking ahead, one of the main challenges that fascinates me is gaining a deeper understanding of electrode-material mechanisms, especially during cycling. In that context, I would like to integrate operando techniques more fully into my research, as they enable monitoring of material changes in real time under conditions that simulate the battery’s actual environment. Such an approach provides insight into mechanisms and kinetics that can significantly contribute to material optimisation,” Dr Raić explains.

“It’s like seeing the inner workings of a clock for the first time – suddenly you understand why some cogs occasionally slip,” she adds.

Sustainability Is Non-Negotiable

From an economic standpoint, she is increasingly focused on sustainability, from material scalability to battery-system recycling. “We don’t just want good performance. We need materials that make sense in a circular-economy context – materials that won’t burden the environment as current technologies do. Sustainability and the circular economy are becoming vital aspects of energy storage, and I believe that integrating these principles into research and development will be key to the future of battery technology.”

Advice for Young Scientists: Patience, Skepticism and Curiosity

Here her scientific philosophy emerges: thorough, critical and interdisciplinary. Dr Raić does not romanticise science. On the contrary, she believes it is crucial to develop resilience, especially in the face of one’s own failures.

“I would advise young researchers aiming for a career in this dynamic and challenging field to cultivate critical thinking above all. In battery research, as in many other scientific areas, we often encounter flashy headlines and results that, upon closer scrutiny and expertise, do not always stand on solid ground. It’s important to distinguish truly significant, reliable findings from those that may not be, and to develop an awareness of context, methodology and reproducibility,” she emphasises, adding: “Poor results aren’t the end of the road. They highlight where deeper digging is needed. Science rarely progresses in a straight line; the best advances often come from mistakes we are willing to analyse.”

Her journey – from preparing silicon nanostructures in local laboratories to participating in international projects such as HEALORB and ADREBO in Slovenia – speaks of a scientist unafraid of complexity, and of a new generation of researchers. Ultimately, what drives Dr Matea Raić is not just curiosity or ambition, but the realisation that tiny particles – atoms, molecules, nanostructures – can create profound change. And it is these changes that will lead us to a greener, more sustainable future.

As the world races towards electrification, it may be at Ruđer – quietly and systematically – that the battery to make that future a reality is being built.