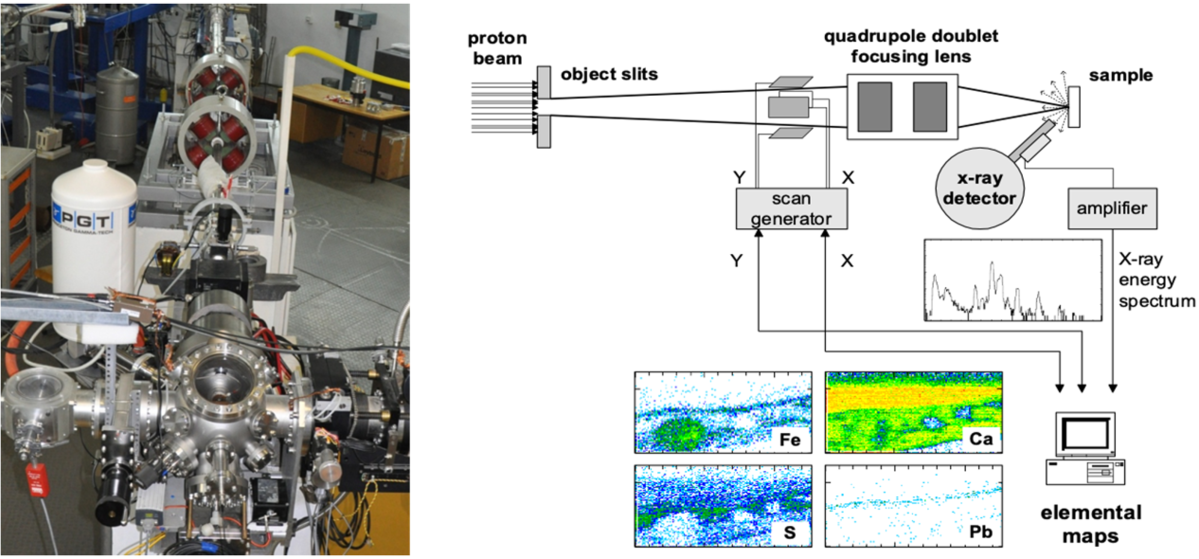

An ion microprobe is a device that uses a system of magnetic quadrupoles (depending on the application, it can be a doublet or a triplet) to focus an ion beam to micrometer size. The focused ion beam is scanned over the sample surface (typically up to 1 × 1 mm²). Available beams include protons (0.4 to 8 MeV) and most other heavier ions up to an ME/q² ratio of 15 MeV. Typical currents used for most Ion Beam Analysis (IBA) techniques, such as Particle Induced X-ray Emission (PIXE) and Rutherford Backscattering Spectrometry (RBS), range between 1 and 1000 pA. The beam spot size depends on the type of ions being focused, their energy, and current.

In the high-current operation mode required for ion beam analysis, PIXE and/or RBS are operated with proton or He ion beams. For the analysis of light isotopes using an ion beam, Nuclear Reaction Analysis (NRA) can be employed, often with a ³He ion microbeam. Typical beam spot sizes in high-current mode can be as low as 1 mm.

In the low-current operation mode of the ion microprobe (ion beam currents < fA), techniques such as Scanning Transmission Ion Microscopy (STIM) and Ion Beam Induced Charge (IBIC) are used. The IBIC technique is utilized for imaging transport properties in radiation detectors and other electronic devices. In this case, the ion microprobe can be used for in-situ studies of material radiation hardness or the creation of single-event upsets in electronic circuits. Under the most favorable conditions, the beam spot size in low-current mode can be as small as 250 nm.

ION BEAM ANALYSIS TECHNIQUES

A variety of ion beam characterization techniques are available at the Ruđer Bošković Institute (RBI) ion microprobe. These include PIXE, RBS, NRA, Particle Induced Gamma-ray Emission (PIGE), Ion Beam Induced Luminescence (IBIL), MeV-SIMS (Secondary Ion Mass Spectrometry), STIM, and IBIC. All these techniques can be used for imaging (e.g., elemental distributions) or for performing quantitative analysis at a specific point or region.

PIXE and RBS

When a charged particle (e.g., a proton) moves through a material, it primarily loses energy by exciting electrons in the atoms it passes by. Electrons in the inner shells of the atom (mainly the K and L shells) gain enough energy to be ejected. Electrons from outer shells then fill these vacancies, which is accompanied by the emission of X-rays. The energies of these X-rays are characteristic of the element. Therefore, if an appropriate detector is used, the recorded spectra can be used to identify the elemental composition of a sample exposed to the beam. PIXE is a relatively simple and multi-elemental analytical technique that can be used to identify and quantify elements ranging from sodium (Na) to uranium (U). PIXE is also a nondestructive technique and is very sensitive for a wide range of measured elements, with detection limits close to 1 ppm (parts-per-million).

Nuclear microprobe beam line (left) and computer control system (right)

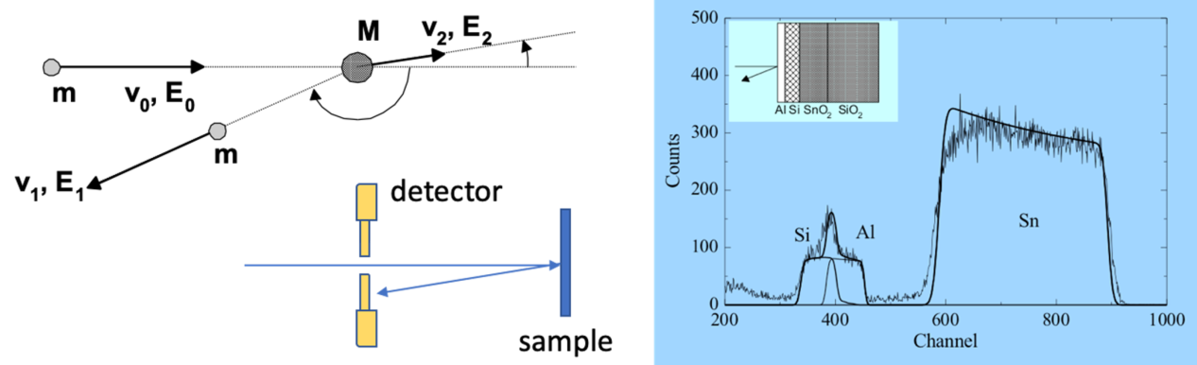

By measuring the energy and intensity of a backscattered beam of high-energy ions (typically protons and alpha particles) impinging on a sample, it's possible to determine the composition and depth profile of elements at and below the sample's surface. While this technique can quantify major sample elements (excluding hydrogen) and thus complements PIXE, RBS is particularly useful for depth profiling. The best results are achieved when depth profiling heavy elements within light substrates.

RBS in chamber setup (left) and example of the energy spectrum (right)

NRA and PIGE

When an accelerated ion (typically a proton) approaches the nucleus of a target atom, the Coulomb force usually repels it. However, if the incident ion has enough energy to overcome the repulsive Coulomb force, it then penetrates through the electrostatic barrier into the nucleus, resulting in interactions with the atomic nucleus. If a nuclear reaction occurs, it can result in the emission of particles and/or gamma rays. The detection of particles (usually done by Si particle detectors) is the basis of NRA (Nuclear Reaction Analysis), while the detection of gamma rays (typically by large-volume Ge detectors) is the basis of PIGE (Particle Induced Gamma-ray Emission). Both techniques can be used in conjunction with PIXE and RBS, and they are mainly employed to quantify the concentrations of low Z elements such as Li, Be, B, C, N, O, F, Na, Mg, and Al.

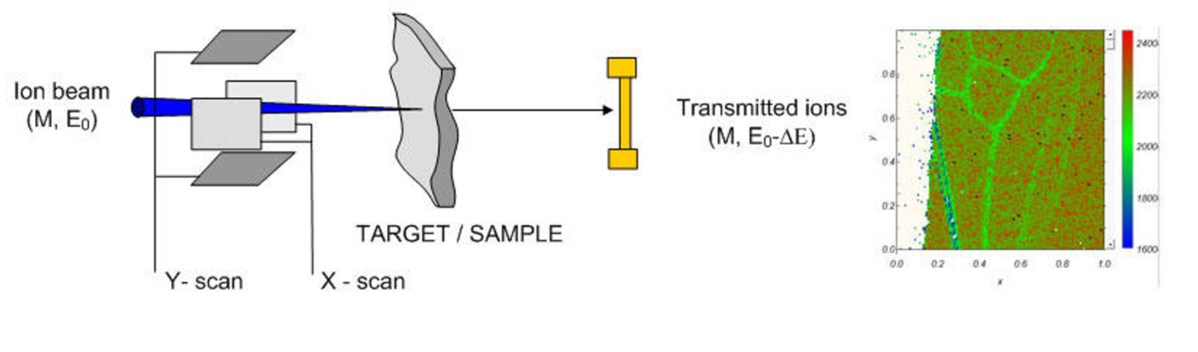

STIM

Ions penetrating a material undergo numerous interactions with the target's electrons and nuclei. During this process, they lose energy and slow down. The ion's energy loss depends on its velocity and charge (not its mass), as well as on the target material. By measuring the energy of a transmitted ion at a specific sample position, variations in its structure and density within the sample can be studied. By using different ion species and their respective energies, a wide range of sample thicknesses can be investigated.

Stim setup on microprobe line (left) and an example of the histogram obtained with this technique (right)

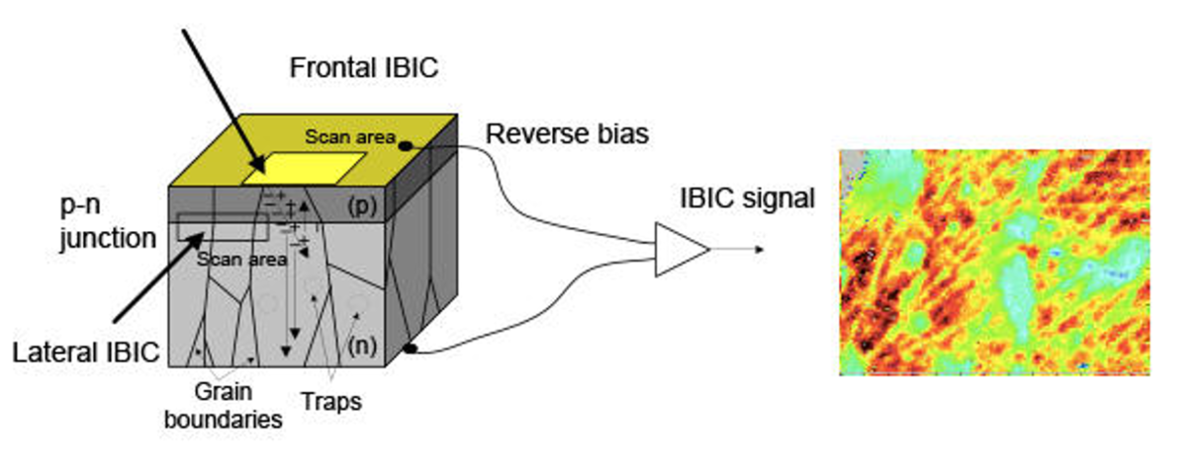

IBIC

Accelerated ions interact with the electrons of atoms in the material, creating numerous ionizations along their trajectories. If ions are stopped in a semiconductor device, the created charge pairs can drift in a built-in electric field (e.g., a pn junction) or in an external field. This will induce a measurable signal at the electrodes. By correlating the ion's position (using an ion microprobe system) with the signal height, images of charge collection properties are obtained. In addition to IBIC imaging, the technique is suitable for quantifying the transport parameters of charge carriers in the materials being tested. With the ability to inject different ion species at varying energies, IBIC can also probe electronic transport at different sample depths.

Frontal and lateral IBIC schematics (left) and example of the energy histogram (right)

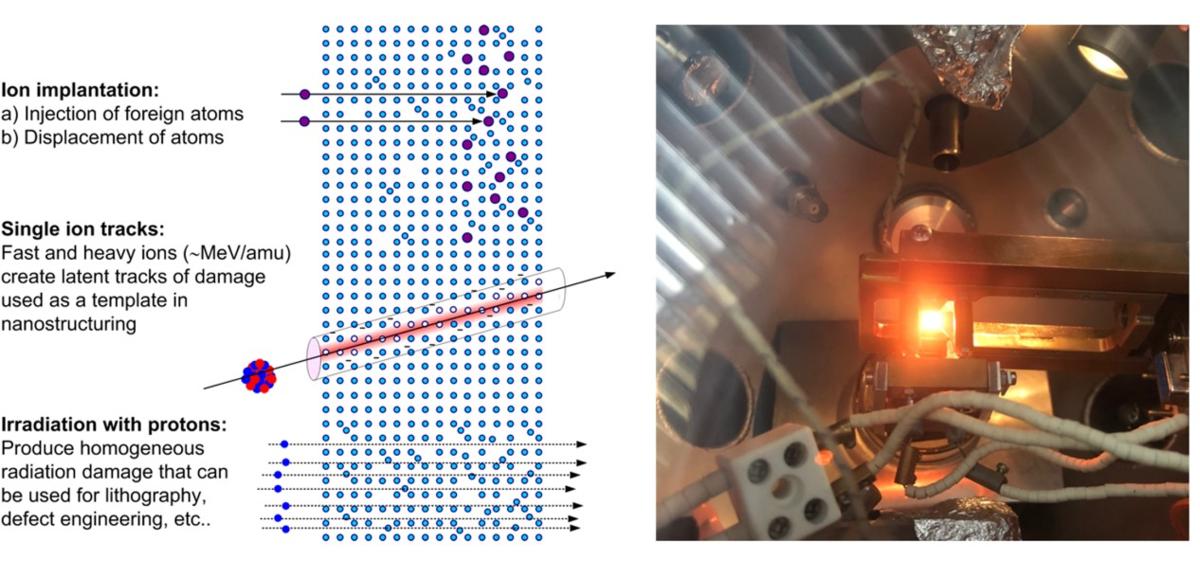

MATERIALS MODIFICATION

In addition to characterisation, focussed MeV ion beams could be also used for materials modification. Proton microbeam could be used for direct writing lithography (e.g. resists as PMMA), or to induce homogeneous regions of radiation damage with reliable control of ion fluence. Heavier ions could be implanted to a certain depth in the sample. A wide span of fluences could be used, from single ions (e.g. luminescence centres) up to extremely high fluence densities (e.g. induction of graphitic lines in diamond by C-ion implantation). On the picture below one can see the in-chamber view during the diamond implantation process. The sample is heated to 750 °C.

Schematics of ion tracks passing through crystal lattice of the material (left) and example of the diamond sample ion beam implantation process in microprobe chamber at 750 °C (right).

TECHNICAL SPECIFICATIONS

Sample viewing and positioning

Sample is viewed by a long working distance microscope with a fixed magnification (1.5 mm field of view). There is also a wide field camera (view field 2.5 cm) Samples are positioned by a 3-axis stage.

Scan control and data acquisition

Ion microbeam position is controlled by a magnetic scanner, driven by the SPECTOR software. Scanning pattern is defined either as a square or arbitrary contour. Typical resolution is 128 or 256 pixels. Scanning speed is defined by the time per pixel and is typically adjusted between 10 and 10000 ms. Maximum scan size depends on the ion beam rigidity, but generally is between 1 and 2 mm. Up to 4 ADCs are used by SPECTOR data acquisition software. Data is stored as summed spectra and elemental images (if the ion beam analysis is done), as well as a raw data list for further processing. In the case of IBIC or STIM measurements, images present average pulse height in each pixel.

Detectors

- 30 mm2 Si(Li) detector for PIXE, minimum sample distance 20 mm.

- 300 mm2 SBD for RBS (annular) positioned at the 170° back angle.

- 100 mm2 SBD NRA detector positioned at the 135° back angle.

Focusing system

For lower rigidity ions (up to ME/q2 = 6 MeV) Oxford triplet focusing is used. For higher rigidity ions, simple doublet is used (only the first two quadrupoles are used). For the low current mode both object and collimator slits are reduced from their default value (100 mm; 1 mm) by 10 times, reducing the current by 4 orders of magnitude or more.

Ion microbeam current

- High current mode: 10 to 1000 pA

- Low current mode: < 1 fA

Scanning speed

- From 10000 ms to 10 ms per pixel adjustable

Sample movement ranges

- x = 100 mm

- y = 25 mm

- z = 25 mm

Sample tilt

- 360° continuous, only around x-axis

Max specimen dimensions

- x = 60 mm

- y = 30 mm

- z = 10mm

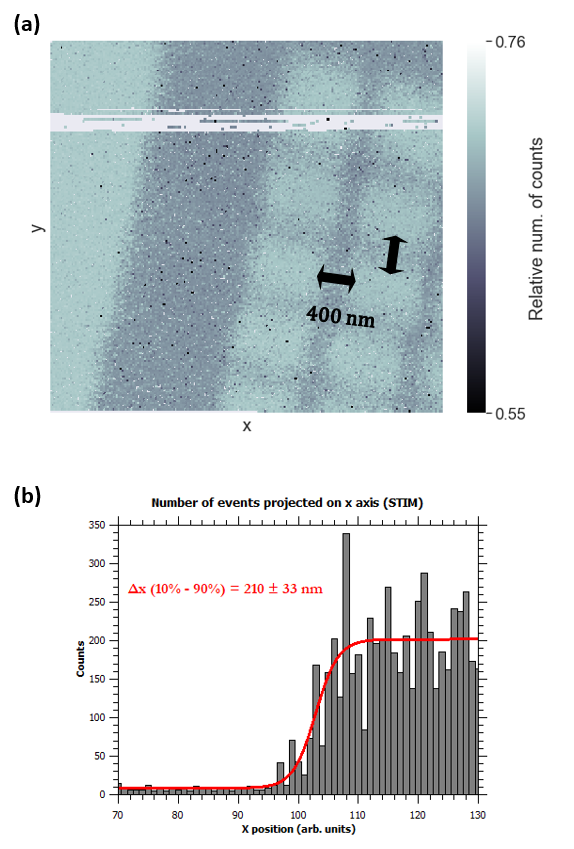

Beam resolution

For most of the employed ions and energies, beam spot can be focused to a 1-2 μm profile, thus allowing the micrometer scale lateral resolution during the imaging of the sample that is being examined. However, sub-micron resolutions can be achieved. On the figure below, an example is shown where a 2 MeV proton beam was scanned over the micro-machined grid with 400 nm bars. In the displayed histogram, one can see that the bars are clearly resolved in both directions. Beam resolution was calculated by fitting the “error function” on the grid bar edge (extracted from the histogram). X-direction resolution is: 210 ± 33 nm. Resolution worsens in the Y-direction, and was estimated around 300 nm.

(a) The number of events collected with the STIM technique, during the 2 MeV focused proton beam scanned over the micromachined grid with 400 nm bars. Bars are nicely resolved and visible in both directions. The horizontal resolution is better than vertical resolution. (b) Error function fit on the grid bar edge data, representing horizontal resolution of the beam.